Distribution / Sales

Frau Marion Schwarz

Tel.: +49 89 900 001 - 21

Email: marion.schwarz@moradelli.com

MORADELLI - IN THE 7. GENERATION

- 1750 Andreas Moradelli works as a master shoemaker and lives with his family in Trento.

- 1790 Andreas Moradelli junior emigrates to Munich and settles as a locksmith in the then suburb of Schwabing.

- 1794 06 December 1794 Andreas Moradelli is accepted as a master locksmith in the Munich locksmith's cooperative.

- 1838 The son of Andreas Moradelli, Karl runs the company and acquires a Renaissance house in the center of Munich, near the Hofbräuhaus, which is still listed in the city books as the Moradellihaus.

- 1870 Carl's sons, Joseph and Alois Moradelli also become locksmiths.

- Carl Moradelli is appointed royal Bavarian court locksmith due to his craftsmanship for the Wittelsbach royal house. The work for Neuschwanstein Castle and Linderhof Castle receives special recognition.

- Optimized cladding for his forge furnaces lays the foundation for industrial production.

- 1890 The Moradelli company is available by telephone. Production moves to the outskirts of Munich, near Goetheplatz.

- 1896 Alois Anton takes over the management of the company

- 1907 The first perforated sheets are produced with a used 50 ton strip press.

- 1925 After the death of her father, Luise Anton takes over the company. Due to the world economic crisis in 1929, the company is severely affected.

- 1945 Reconstruction of the company, which had been badly damaged by the war, and the commissioning of additional perforating presses, shears and press brakes.

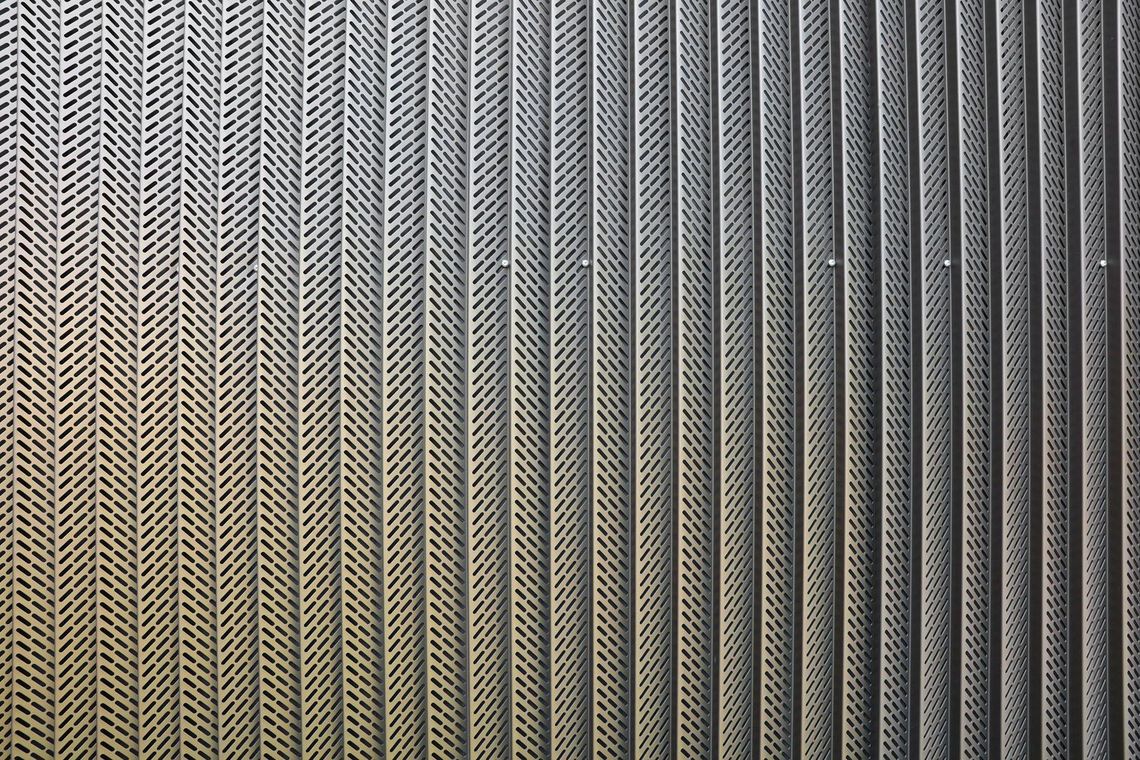

- 1960 The "economic miracle" ensures full order books, in particular perforated plates, filter tubes, radiator cladding and machine housings are produced.

- 1972 The Olympic Games in Munich bring a further boost to the local economy. Moradelli recognizes the trend and produces perforated sheets for architecture and construction.

- 1976 Further expansion of operations also increases the need for space. The company moves to the outskirts of Munich. Son-in-law Ludwig Sauer moves the company to Kirchheim in the east of Munich, where there is a direct link to the freeway.

- 1978 In addition to perforated sheets, embossed products become increasingly important.

- 1983 First use of a punching nipple machine in the perforated sheet sector.

- 1985 A high-performance perforating press with coil device is purchased.

- 1990 Further enlargement of the production halls and construction of a new administration building.

- 1997 Commissioning of the first fully automatic punching line.

- 1999 Purchase of an adjacent plot of land - to cover future space requirements.

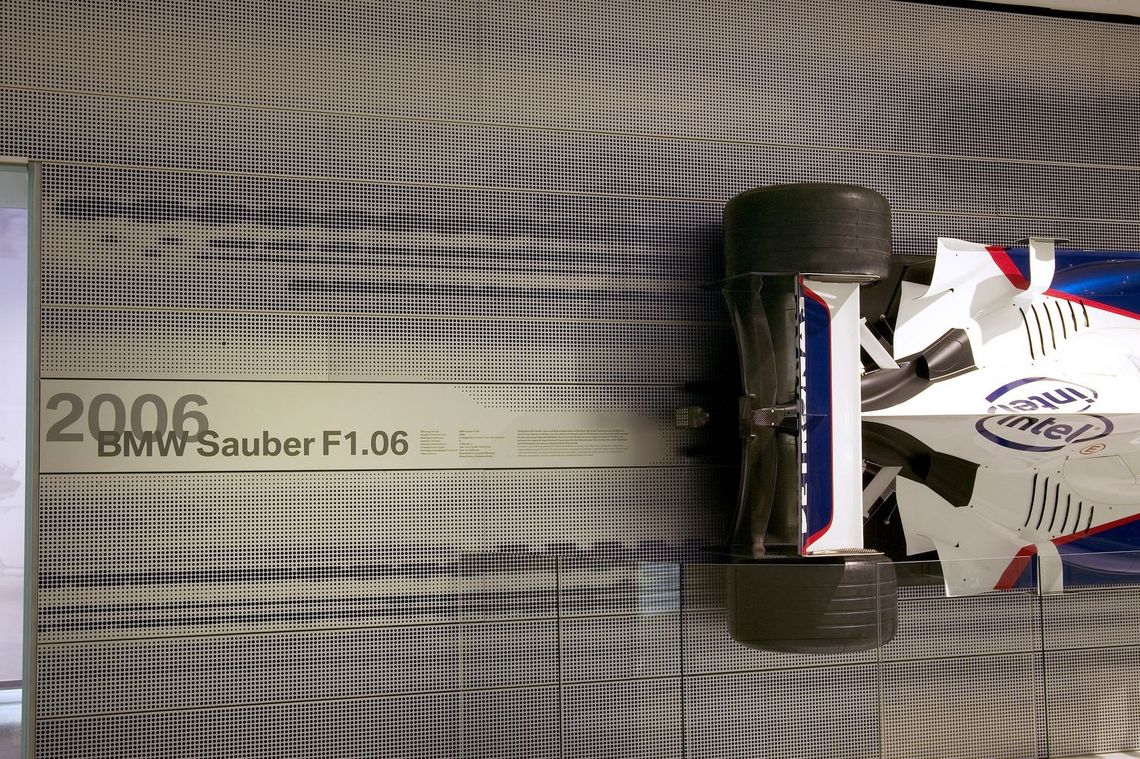

- 2006 Entry into laser technology through the use of a fully automated punching-laser machine. Production runs in 3 shifts.

- 2007 Development of the honeycomb-shaped perforated and folded exterior facades for the AUDI sales terminals, in close coordination with Audi and the architects ASW ( Allman, Sattler, Wappner).

- 2008 Moradelli obtains the status of Audi contract supplier. Fully automated production of facade sheets and worldwide, ready-to-install delivery to all Audi terminals.

- 2010 Expansion of the bending technology by an automated swivel bending line as well as the use of an additional punching laser line.

- 2012 Entry into the technology of waterjet cutting. By using a shuttle table, water jet cut sheets are produced automatically.

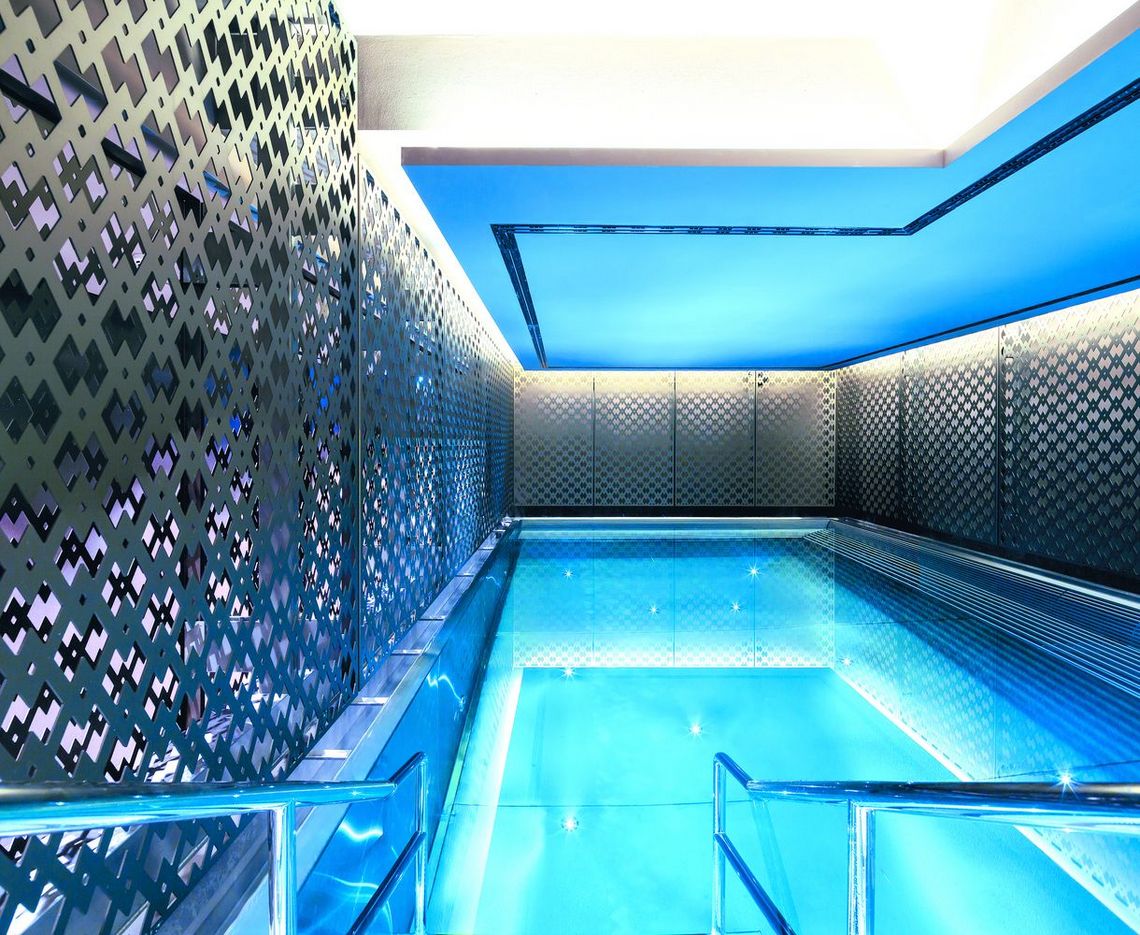

- Today... Manufacturing complex components with a focus on perforated plates, stamped plates, laser components and waterjet cut parts. Ready-to-install parts can be supplied to fit exactly. They are used especially in the field of facades, wall claddings, balcony railing fillings, radiator claddings, filters, filter tubes, sieves, housings, covers, plant engineering and many more...